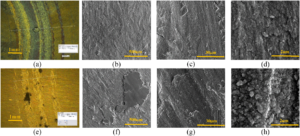

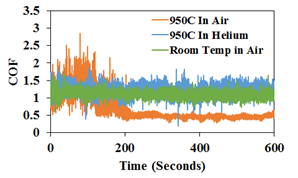

The project is focused on a comprehensive experimental plan to investigate and compare the friction, surface damage (wear, fretting, self-welding, corrosion/oxidation) and contact response of tribo-pairs consisting of alloys 800H and 617 in simulated HTGR He and also in air (room and high temperature).Micro/nano-indentation is being used to characterize the top oxidized layer’s mechanical properties. This will contribute to the design and licensing of HTGR/VHTR in Nuclear Regulatory Commission (NRC) especially with the forthcoming addition of Alloy 617 to the ASME Code for HTGR/VHTR. Besides, micro/nano-mechanical testing and material characterization will be performed in normal and simulated HTGR conditions along with analytical/numerical modeling to obtain a fundamental knowledge of failure mechanisms and tribological response as well as to develop predictive models. In addition, this research aims to identify and suggest solutions to mitigate tribological problems with these materials under HTGR/VHTR conditions through investigating different alternative solutions such as optimizing the design as well as operating conditions, and surface modifications, such as surface topography changes, treatments, and HT super hard coatings.